About Aluminized Zinc Plate

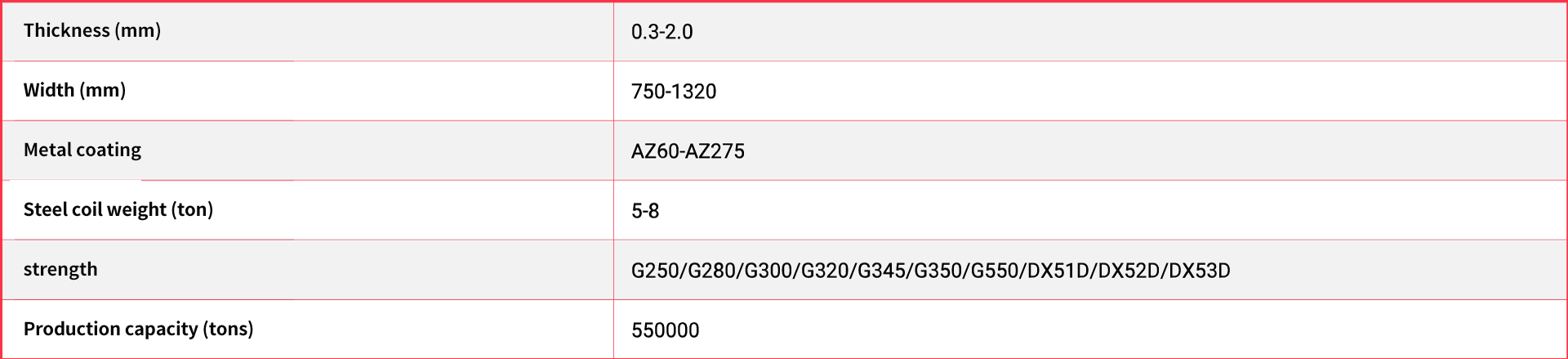

Aluminized zinc plate refers to a steel plate coating that adds aluminum (passivation protection) on top of zinc, with a general composition of 55% aluminum, 43.5% zinc, and 1.5% silicon. It has excellent atmospheric corrosion resistance, which is 2-4 times that of galvanized plate. It also has the high-temperature corrosion resistance of aluminum plate, with a smooth surface and a good appearance.

Usage: Building roofs, walls, electrical cabinets, household appliances, automobiles, color coated substrates, etc

Project Case

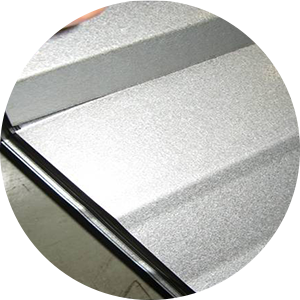

Product display

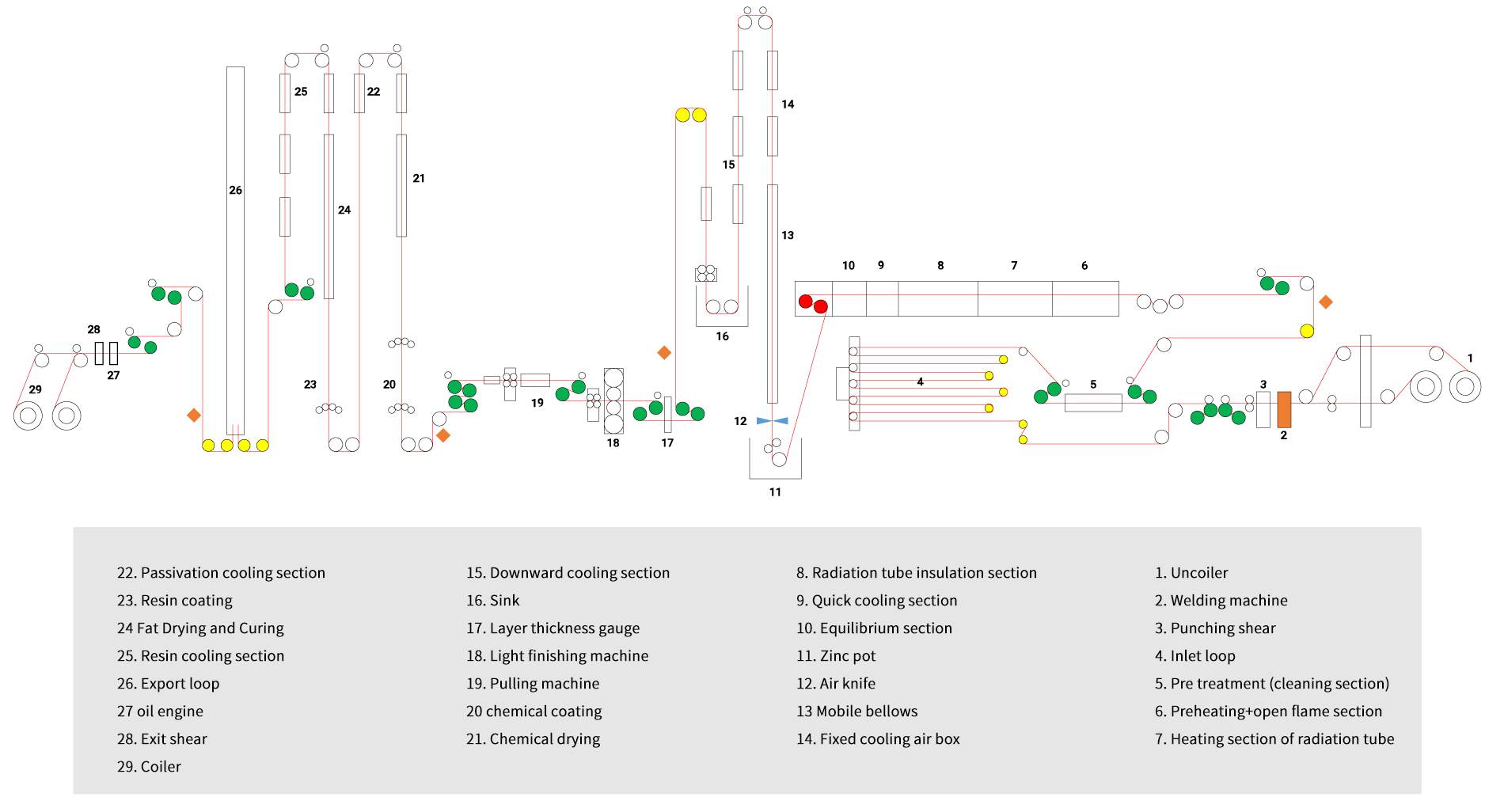

pretreatment

After uncoiling, the steel coil is cleaned and its composition is reduced to the extent that it can be galvanized through the degreasing section and reduction furnace.

Central section

After passing through a zinc pot, a zinc layer is coated on the surface of the steel plate, and then cooled and shaped by a cooling tower.

Post processing

After finishing, straightening, and passivation, it is rolled onto the winding machine to form the final product.

Product Advantage

Product Advantage

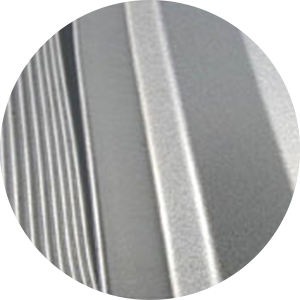

Unique Tiny Zinc Flower

Shandong Gangzhijie Products

Ordinary products

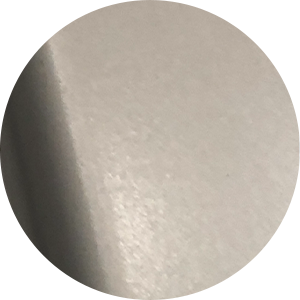

Uniform Zinc Flower

Shandong Gangzhijie Products

Ordinary products

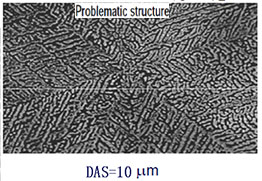

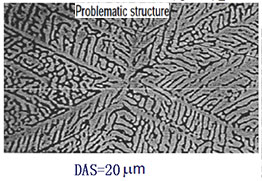

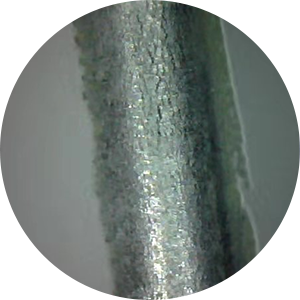

Small dendrite spacing

Note: The dendrite spacing is an important factor in measuring the corrosion resistance life of aluminum zinc plated products, and products with dendrite spacing greater than 20um are not acceptable.

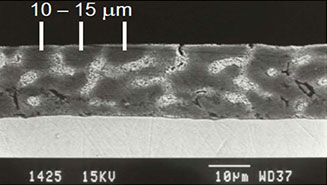

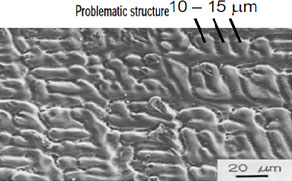

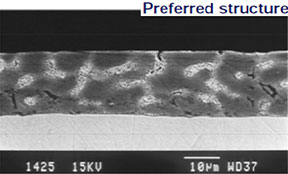

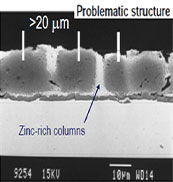

Electronic microstructure

Optical microstructure - Unfinished and straightened

Small dendrite spacing - Shandong Gangzhijie product

Large dendrite spacing - regular products

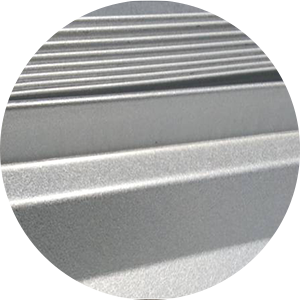

Ideal coating structure

Ideal Plating Structure - Shandong Gangzhijie Products

Bamboo shaped problem coating structure - ordinary products

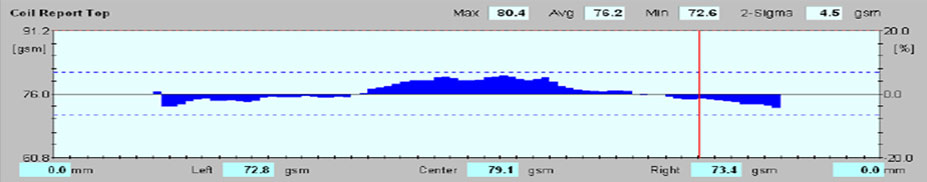

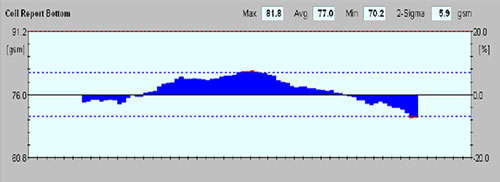

Uniform amount of plating on the board surface

Uniform distribution of coating amount - Shandong Steel Zhijie products

Uneven distribution of coating amount - regular products

Processing lubrication advantages

Shandong Gangzhijie adopts a two coating and two drying process for the post treatment of aluminum zinc plating, which involves passivation followed by drying and cooling, followed by applying fingerprint resistant and drying cooling. The fingerprint resistant film is thicker and cured more thoroughly, resulting in relatively better processing lubricity.

Aluminum Zinc Plated Plate Pressing - Shandong Gangzhijie Product

Aluminum Zinc Plated Plate Pressing - Ordinary Products

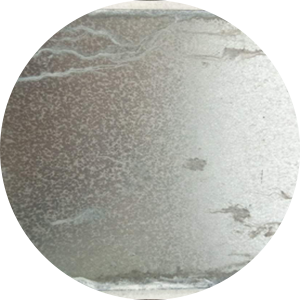

Better anti dimming function

Unique surface treatment technology, double coating and double drying, aluminum zinc magnesium passivation conversion layer added with special anti-corrosion substances, the product has better anti darkening function.

Shandong Gangzhijie Products

Ordinary products

Cracking degree at the processing bending edge

Shandong Gangzhijie's aluminum zinc coating formula is more advanced. Under the same substrate thickness, strength, material, coating amount, and bending test conditions, the cracking degree and number of cracks in the bending sheet are smaller.

Shandong Gangzhijie Products

Ordinary products

High strength and high elongation

The uniquely developed G550 high-strength dual phase steel achieves dual guarantees of high strength (YS>=550MPa) and high elongation (E>=12%) through the addition of alloy elements, suitable for more demanding bending requirements, such as building keels, sewer pipes, etc.

Aluminum and zinc plating processing - Shandong Gangzhijie products

Aluminum zinc plating processing - ordinary products

Corrosion resistance of coating

Special anti-corrosion substances are added to the aluminum zinc plating layer of Shandong Gangzhijie, while special anti-corrosion substances are added to the passivation conversion layer, resulting in better corrosion resistance of the product; The post plating treatment adopts a two coating and two drying process, which involves passivation followed by drying and cooling, followed by coating with fingerprint resistance and drying and cooling, resulting in better durability and anti blackening resistance of the product.

Aluminum Zinc Plated Plate Salt Mist - Shandong Gangzhijie Product

500h neutral salt spray, white rust and black rust area<5%

Aluminum zinc plated smooth plate salt spray - ordinary products

500h neutral salt spray, white rust and black rust area>5%

quality assurance

quality assurance

Warranty Commitment

test report

Experimental equipment

/ 135 8971 6663

/ 135 8971 6663